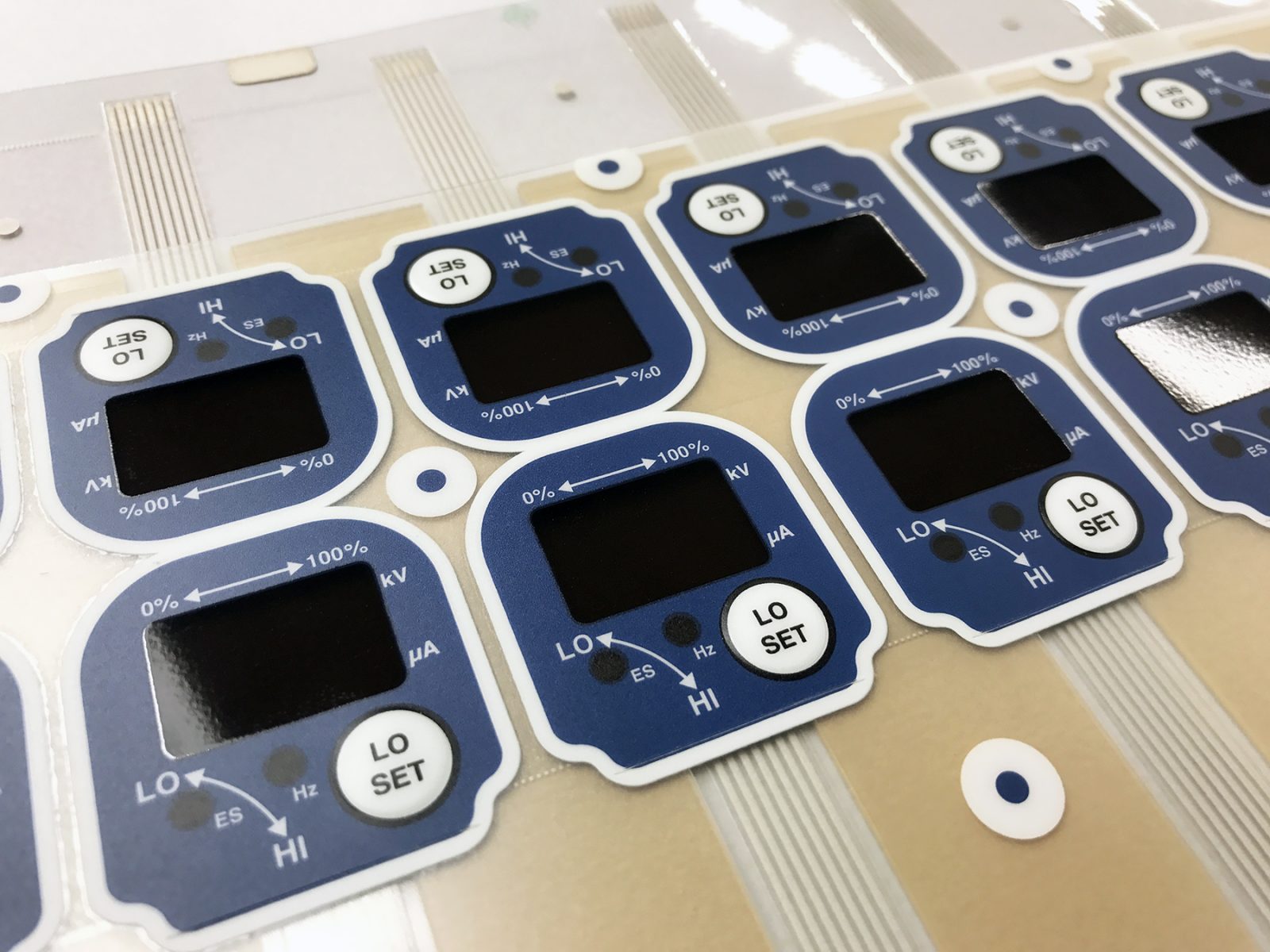

An creative membrane switch manufacturer can provide modern features and materials.

An creative membrane switch manufacturer can provide modern features and materials.

Blog Article

Everything About Membrane Switch: Recognizing Its Style and Capability

When you believe concerning the control interfaces in modern-day gadgets, membrane layer buttons typically come to mind. These parts are much more than simply buttons; they blend style and functionality flawlessly. Recognizing how they work and what makes them reliable can change your viewpoint on daily electronic devices. There are subtleties to their style and efficiency that you could not be mindful of. Allow's discover what collections membrane layer switches over apart from other control systems.

What Are Membrane Layer Switches?

Their seamless nature makes them easy to tidy and immune to dirt and moisture, an essential attribute in numerous environments. Membrane switches can additionally be tailored pertaining to shape, size, and graphics, permitting manufacturers to produce distinct user interfaces customized to specific items. And also, they're lightweight and slim, which aids in decreasing the general mass of tools. In general, membrane layer switches play a substantial function in boosting customer experience throughout a vast array of applications.

Just How Membrane Switches Over Job

When you press a secret on a membrane layer switch, it triggers an uncomplicated yet reliable mechanism. membrane switch manufacturer. The top layer, usually made of flexible material, pushes down onto a conductive layer underneath it.

You'll notice that the tactile responses varies based on the switch design, using either a soft click or an extra noticable feedback. Once you launch the trick, the membrane go back to its original setting, resuming the circuit and quiting the signal. This procedure occurs practically instantaneously, ensuring a receptive user experience.

Membrane layer switches are preferred as a result of their durability and resistance to dirt and wetness, making them optimal for different applications, from family devices to clinical gadgets. Comprehending this procedure assists you appreciate their widespread usage.

Key Parts of Membrane Buttons

Recognizing the essential elements of membrane buttons is essential for grasping their capability and layout. At the core, you'll locate the visuals overlay, which offers the aesthetic user interface for users. Under that, there's a spacer layer that divides the circuit layers, making certain that they do not make get in touch with until pushed. The circuit layer is where the magic takes place; it is composed of conductive traces that finish the circuit when you push the button. Another essential element is the glue support, permitting the switch to follow surfaces safely. Finally, the safety layer guards versus environmental variables and use, extending the button's life-span. Each element plays a considerable function in guaranteeing trusted efficiency and customer communication. By understanding these elements, you'll acquire insight into just how membrane layer switches over operate and their value in various applications.

Materials Used in Membrane Layer Switch Style

The efficiency and durability of membrane layer switches greatly depend on the materials made use of in their style. You generally come across polyester and polycarbonate as primary substratums due to their outstanding strength and flexibility. These products stand up to scratches and chemicals, making them optimal for requiring environments.

The conductive layers typically utilize silver or carbon, chosen for their reliability and conductivity. membrane switch manufacturer. Silver supplies exceptional efficiency, while carbon is an affordable option. For the overlay, you may consider a matte or glossy finish, relying on your visual demands and customer experience

Adhesives play an essential function as well; they bond layers securely and ensure durability. Ensure to choose adhesives that endure ecological factors like temperature level and moisture. Don't forget the relevance of a great printing technique for graphics, as it boosts both capability and visual allure. Choosing the ideal materials will guarantee your membrane layer button stands the test of time.

Layout Factors To Consider for Membrane Switches

While developing membrane layer switches, it's essential to take into account various aspects that influence their functionality and customer experience. Beginning by More Bonuses concentrating on the layout and button size; make particular they're user-friendly and simple to browse.

Validate your layout accommodates environmental elements, like moisture or temperature level variations, which can influence efficiency. By very carefully thinking about these aspects, you'll produce a membrane button that boosts usability and contentment.

Applications of Membrane Layer Switches

Membrane switches are versatile elements found in different applications, from commercial equipment to consumer electronics. You'll see their impact in machines that call for resilient user interfaces and in gadgets that benefit from sleek designs. Recognizing these applications aids you appreciate the capability and usefulness of membrane layer switches in daily technology.

Industrial Equipment Usage

When you're aiming to improve the capability of commercial tools, membrane layer buttons supply a reliable option that combines durability with user-friendly style. These buttons are ideal for harsh environments, giving resistance to dust, wetness, and chemicals. You'll locate them in control panels for manufacturing devices, cooling and heating systems, and medical tools, where precision and responsiveness are essential. Their reduced account means basics they fit perfectly right into various equipment, saving important space while maintaining simplicity of usage. With personalized graphics and backlighting options, you can develop an user-friendly user interface for drivers, enhancing effectiveness and safety and security. Plus, their long life expectancy reduces maintenance prices, making them a wise financial investment for your industrial applications. Welcome membrane layer switches to streamline your operations and improve total performance.

Customer Electronics Combination

In the domain of consumer electronics, membrane layer switches play a vital function in boosting individual communication and device capability. Membrane layer buttons additionally guarantee durability and resistance to dust and wetness, prolonging the life expectancy of your electronic devices. By selecting membrane buttons, you improve not simply the functionality however likewise the style of your tools, making day-to-day communications smooth and satisfying.

Benefits and Downsides of Membrane Layer Switches

While membrane switches supply a range of benefits, they also come with some drawbacks that check my source you should consider. One considerable advantage is their small layout, making them suitable for space-constrained applications.

Membrane buttons can have a much shorter lifespan compared to mechanical switches, particularly under hefty use. They can also be less responsive, which could influence user feedback throughout operation. Balancing these pros and cons will certainly aid you establish if membrane layer buttons are the right fit for your task.

Often Asked Questions

For How Long Do Membrane Layer Changes Generally Last?

Membrane layer changes generally last in between 5 to one decade, relying on usage and environmental conditions. You'll wish to evaluate factors like wear, direct exposure to moisture, and temperature variations to assess their longevity efficiently.

Can Membrane Switches Over Be Personalized for Details Styles?

Yes, you can customize membrane switches to fit specific layouts (membrane switch manufacturer). You'll have the liberty to choose colors, forms, and formats that match your project's demands, guaranteeing they mix effortlessly with your overall aesthetic

What Is the Expense Array for Membrane Switch Over Production?

The cost array for membrane layer switch manufacturing normally drops in between $1 and $10 each, depending upon variables like layout complexity, quantity, and products. You can obtain quotes from producers to discover the very best choice.

Are Membrane Layer Changes Water-proof or Immune?

Membrane layer switches can be developed to be water resistant or resistant, relying on products used and building approaches. If you need them for wet atmospheres, assure you specify those requirements throughout the design process.

Just How Do Membrane Layer Switches Contrast to Standard Buttons?

Membrane switches are usually thinner and more versatile than conventional buttons, supplying a sleek design. They're commonly less complicated to clean up and integrate, however could not supply the responsive comments you're utilized to with mechanical alternatives.

Final thought

Report this page